In modern material handling and bulk transport, specialized belts make the difference between seamless flow and constant downtime. This guide explains the chevron conveyor belt in clear terms — what it is, where it’s used, and how to pick the right model for your operation. If you’re researching options, learn more about reliable manufacturers and resources, including products like the chevron conveyor belt and trusted partners such as chevron conveyor belt suppliers.

Overview: What Is a Chevron Conveyor Belt?

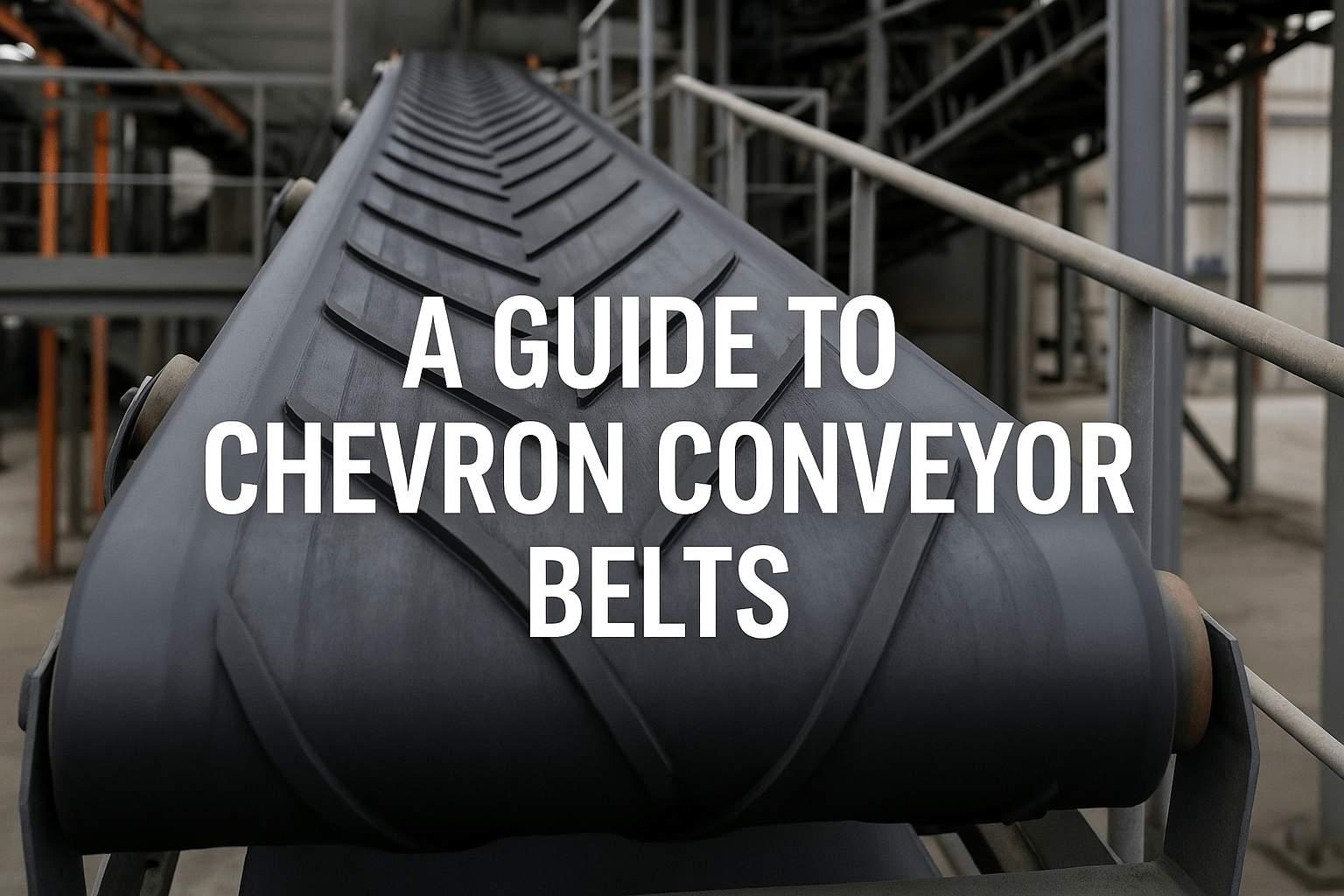

A chevron conveyor belt is a type of conveyor belt engineered with raised V-shaped patterns (chevrons) molded or stitched into the top surface of the belt. These distinctive patterns create friction and a small ridge structure that prevents materials from slipping backward on steeper inclines. The design makes chevron belts ideal for transporting loose, granular, or bulk items up moderate to steep slopes where a flat belt would allow slippage. For a quick product reference, check the detailed specification and product images for the chevron conveyor belt or contact known chevron conveyor belt suppliers for custom profiles.

Why Use a Chevron Conveyor Belt?

Chevron belts solve the age-old problem of uphill slippage. Unlike standard flat belts, they provide mechanical grip through their profile which lifts and channels material upward. This is especially useful in industries where space is limited and chutes or ramps must be compact with a steep angle — for example, in mining, aggregate handling, grain handling, food processing, and packaging. If you need a reliable uphill conveying solution, exploring the features and options from established vendors such as the chevron conveyor belt and lining up quotes from experienced chevron conveyor belt suppliers is a practical first step.

Design & Material Options

Chevron belts come in many compound materials, including rubber, PVC, and polyurethane. Rubber remains the most common due to excellent traction, durability, and resistance to abrasion. The chevron pattern can be molded directly into the rubber surface or applied as separate cleats depending on the application. Manufacturers vary chevron height, angle, and spacing to match the required incline and material characteristics. For instance, coarser aggregates benefit from higher, widely spaced chevrons, while fine powders may require closer, lower chevrons to prevent buildup. When selecting materials and pattern geometry, consult technical specs and reach out to reputable vendors—many leading chevron conveyor belt suppliers publish slope charts and load recommendations.

Common Applications by Industry

Industries that commonly use chevron belts include mining and quarrying (moving ore and aggregates), agriculture (grain elevators and seed handling), recycling (transporting mixed materials up sorting lines), food processing (bulk ingredients on inclined conveyors), and construction (moving sand and gravel). In each scenario the goal is the same: maintain throughput while preventing rollback. Combining the correct belt compound with a suitable support and skirt system also reduces product spillage and extends belt life. Purchasing decisions should consider operating temperature, chemical exposure, and whether FDA/food-grade compliance is required — topics that experienced chevron conveyor belt suppliers can advise on.

Key Advantages of Chevron Belts

The main benefits of chevron conveyor belts include improved traction on steep inclines, reduced material rollback, minimized need for additional hold-down devices, and greater flexibility in plant layout. Additionally, because the chevron profile actively channels material, there tends to be less lateral spillage and better control for lighter or damp products. Properly selected and installed chevron belts can increase conveying efficiency and lower the energy required to move materials uphill. When comparing vendors, evaluate long-term service, spare parts availability, and whether the supplier — for example, reputable chevron conveyor belt suppliers — offers installation and maintenance support.

How to Choose the Right Chevron Conveyor Belt

Selecting the right belt involves reviewing incline angles, material bulk density, desired throughput, belt width, and environmental conditions. Start by calculating the maximum angle of incline and the peak capacity (tonnes or cubic meters per hour). Use those numbers to select a chevron height and spacing that prevent slippage while avoiding unnecessary buildup. Decide on belt material based on abrasion, oil, or chemical exposure; for food and pharmaceutical uses, confirm hygienic compliances. Also check tensile strength and splice type options (vulcanized splices often offer the strongest joints). For specifics and sample recommendations, request datasheets and guidance from established chevron conveyor belt suppliers.

Installation & Maintenance Best Practices

Proper installation includes ensuring correct belt tracking, tensioning, and cleat alignment. Misalignment or poor tension can cause premature wear or chevron detachment. Install appropriate skirtboards and sealing where spillage is a concern. Regular maintenance checks should include chevron wear inspection, splice integrity, and conveyor frame straightness. Cleaning is also important — material buildup between chevrons decreases performance. For complex installations, many buyers find it helpful to work with suppliers who provide on-site commissioning and training; ask potential chevron conveyor belt suppliers about these services before purchase.

Typical Costs & Lead Times

Cost depends on belt width, compound, chevron geometry, and required tensile rating. Rubber chevron belts with higher tensile ratings and custom cleat patterns generally cost more and take longer to manufacture. Stock widths and common chevron profiles may be available faster from local distributors, while bespoke designs require longer lead times. For a realistic budget and delivery schedule, request formal quotes from multiple vendors and compare total lifecycle costs — not just initial price. Reputable chevron conveyor belt suppliers usually provide pro forma quotes that include installation, warranty terms, and recommended spare parts.

Sustainability and Lifecycle Considerations

As operations increase focus on sustainability, consider belt lifetime, recyclability, and energy efficiency. Durable compounds that reduce replacement frequency contribute to lower embodied energy and waste. When possible, select suppliers that offer recycling programs for worn belts or belts that use more recyclable materials. Optimizing conveyor layout and belt selection also reduces the total conveyor horsepower required, improving operational energy efficiency. Engage with suppliers to understand end-of-life options and inquire whether they provide take-back or recycling schemes — many responsible chevron conveyor belt suppliers can advise on greener choices.

Frequently Asked Questions (FAQ)

- Q: What incline angles are chevron conveyor belts suitable for?

- A: Typical chevron belts handle moderate to steep inclines, often between 15° and 45°, but maximum safe angle depends on chevron height, spacing, belt material, and product characteristics. Consult technical charts from your supplier to match angle and chevron geometry.

- Q: Can chevron belts be used for food products?

- A: Yes — but choose food-grade compounds (FDA-compliant where required) and hygienic profiles that minimize harbor points. Always verify certifications and cleanability with your supplier.

- Q: Are molded chevrons better than stitched cleats?

- A: Each has pros and cons. Molded chevrons are seamless and easier to clean, while stitched cleats can be replaced individually in some designs. Application, budget, and maintenance strategy will determine the best option.

- Q: How do I find trustworthy chevron conveyor belt suppliers?

- A: Look for vendors with clear product datasheets, installation support, warranty terms, and positive industry references. Request sample specifications and installation photos — and consider suppliers who offer site surveys and after-sales maintenance. You can begin by reviewing established product pages and contacting proven chevron conveyor belt suppliers.

Conclusion

Choosing the right chevron conveyor belt is a combination of matching belt geometry, material selection, and supplier expertise to your operational needs. These belts provide an effective solution whenever uphill conveying and slip resistance are required. For product details, technical specifications, and purchases, explore product pages and contact reliable partners — for example, review the chevron conveyor belt and reach out to known chevron conveyor belt suppliers to get tailored recommendations, formal quotes, and service options. With the right combination of design and supplier support, a chevron belt can dramatically improve throughput, reduce spillage, and lower long-term operating costs.